The English version of this homepage is currently under construction. Please excuse not all pages being translated, yet

The company GSP (Gesellschaft für Schwingungsuntersuchungen und dynamische Prüfmethoden mbH – Engineering Consultants for Vibration Analysis and Dynamic Testing Methods) was founded in 1991 by Dr.-Ing. Oswald Klingmueller. Since January 2023 GSP became part of the GuD group.

The continuity of the services of GSP, which has been operating successfully for over 30 years, will continue as usual, also after the retirement of the founder.

Managing directors are Dr.-Ing. Silke Appel, Dipl.-Ing. Christian Mayer and Dr.-Ing. Matthias Schallert.

All companies in the GuD-network and their employees work in a close collaboration, so that this well-founded know-how is also available in the future and a customer-specific and optimized service is guaranteed.

Dr.-Ing. Matthias Schallert is leader of the workgroup „pile integrity testing“ of AK 2.1 „Piles“ of the German Geotechnical Society (DGGT) and is member of the commitee NABau NA 005-05-07 AA „Foundation soil, Piles“. The workgroup AK 2. is responsible for the edition of the “Recommendations on Piling (EA-Pfaehle)”.

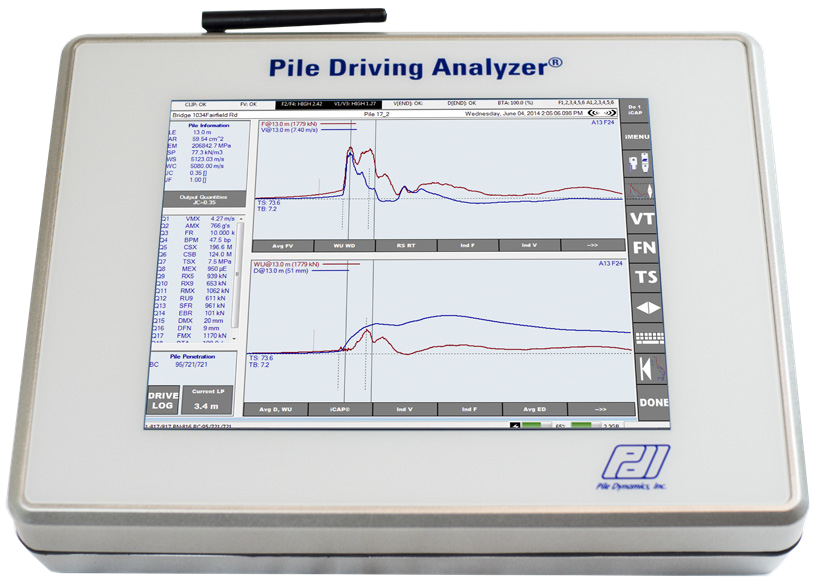

GSP is representative of Pile Dynamics, Inc., Cleveland – the worldwide leading manufacturer of measuring technology, hardware and software for dynamic pile testing. This representation covers German-Speaking countries plus Belgium, The Netherlands and Luxembourg.

• Training on behalf of PDI

GSP provides training in use of PDI equipment on sites also outside the countries mentioned above (e.g. Emirates, Georgia, Guinea, Kazakhstan, Nigeria, Peru, Russia, Turkey).

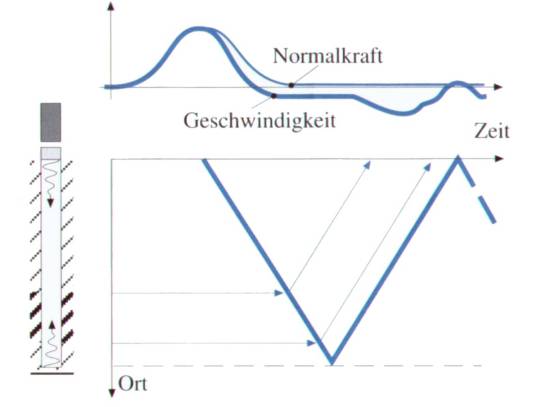

• Workshops and Seminars

GSP organizes workshops and seminars (in German and English) in theory and practice of dynamic pile load testing and pile integrity testing at regular intervals. For more current information please click here.